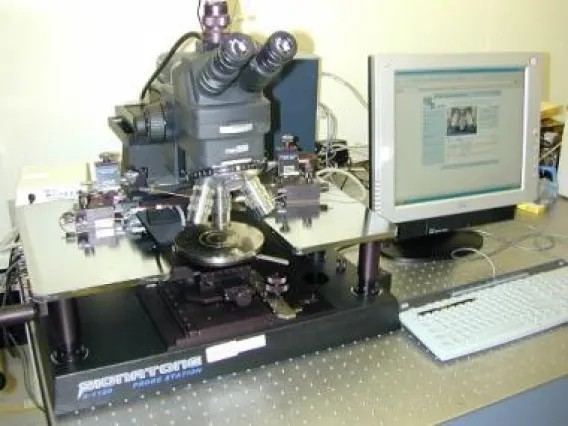

Signatone 1160 Probe Station Microscope

Allows users to view samples and save digital images. Current objectives are 4X, 20X, 40X. Scope can accommodate any size sample and is connected to a computer with internet access. Tool can also be set up for parametric probing of devices.