LP-III Vapor Prime Oven

The LP III Vapor Prime oven. It is located within the class-100 cleanroom.

The LP III Vapor Prime oven. It is located within the class-100 cleanroom.

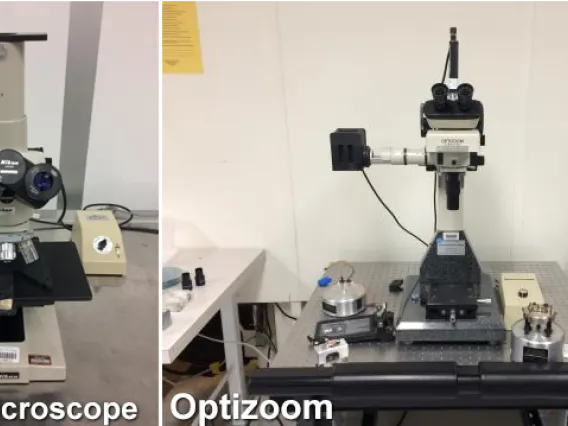

There are a few locations throughout the class 100 cleanroom that you will find microscopes. There is only one location to find the Nikon Optizoom which allows for more advanced magnification. These microscopes are often utilized to analyze the structural integrity of various degrees such as bonds, imperfections, and situational accuracy.

A sturdy reliable profilometer used for measuring film thickness, step height, and surface morphology located inside our Class 100 cleanroom.

A reliable platform used in spin coating primers, photoresists, and polymer coatings located in the lithography area of our Class 100 cleanroom.

Located in our Class 100 cleanroom, the thermal oxidation furnace is primarily used for growing a thermal oxide layer on silicon or annealing clean substrates that have no exposed metal layers. Wafers and substrates less than 5" in diameter can be accommodated. Oxidation is performed at high temperatures of around 1000C either utilizing dry oxygen or wet utilizing a bubbler. No exposed metals are allowed inside the tube.

Located in our Class 100 cleanroom, this system allows for the thermal deposition of metals including Cu, Al, AlSi, In, etc. Deposition occurs under high vacuum. In its current configuration, this system is more suitable for deposition of thin films of more than a hundred nanometers or so.

Located in our Class 100 cleanroom, our BOC Edwards Auto 306 is an electron beam evaporation system used for deposition of ultra pure films of metals as well as fused silica. Fully reproducible parameters provide consistent, repeatable deposition results. The most common metals deposited using this system at MFC are Au, Cu, Ti, Cr. System can deposit up to four different materials in series in the same run. This system is most suitable for thin films of a few nanometers to a few microns.

Electron Beam Manuals

Located in our Class 100 cleanroom's lithography area, our double-stacked Semitool SRD will winse wafers to the required resistivity using ultra-pure water and dry wafers using hot UHP N2. The system is currently set up to handle both 100mm and 150mm wafers.